hardness test specimen size|how to measure hardness : solutions Measuring hardness has a number of benefits in comparing materials and providing quality control in manufacturing and hardening processes. This article will discuss hardness testing, its definition, how it works, its types, . Resultado da Craving something new? Check out Thumbzilla's newest videos - every day hundreds of new porn clips are added to our site. Thumbs up motherfuckers.

{plog:ftitle_list}

Explore short and medium-term Cowabunga Coin price prediction analysis and check long-term Cowabunga Coin forecasts for 2025, 2030, and beyond 📈 🤖 🚀 Our algorithm is still .

Measuring hardness has a number of benefits in comparing materials and providing quality control in manufacturing and hardening processes. This article will discuss hardness testing, its definition, how it works, its types, .

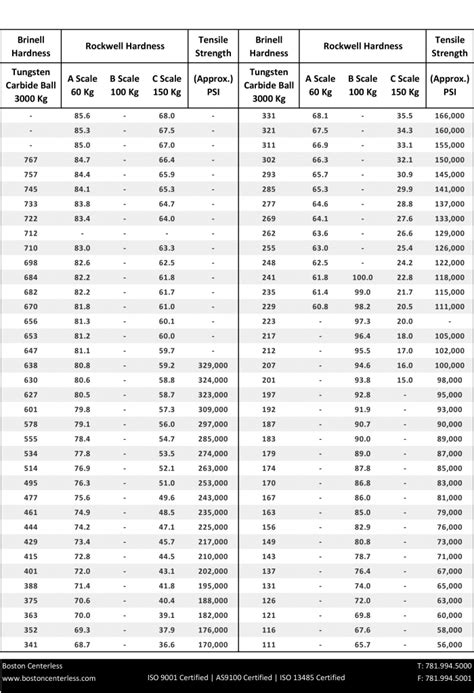

Find the minimum thickness for regular Rockwell or superficial Rockwell testing here. Download as PDF or get the thickness in inches or mm right away.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the optical Vickers method, in which a pyramid-shaped indenter is pressed into a specimen, the Brinell method uses .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series .

Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics.

Sample Size. The smaller the part, the lighter the load required to produce the required indentation. On small parts, it is particularly important to be sure to meet minimum thickness .A standard specimen of 6.4mm (0.25 in) thickness is either molded or cut from a sheet. Data: The hardness is read directly from the dial with either the R, L, M, E or K scales. The higher the .

Rubber Impact Resiliency Tester service

standards for hardness testing

Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this .The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts. . Max sample size: 190 x 254 mm. The largest .

hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds, depending upon the size and hardness of the specimen, as well as pre-load and .The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- . The preload is applied to the sample and held for a specific time. For Rockwell methods the preload is 10 kg. . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness .

Max sample size: 190 x 254 mm. The largest cut-off machine in its field, giving you all aspects of the sectioning process in one automatic machine. . - using a DuraVista-40 hardness testing machine 1. Place your sample on the stage. 2. Click and drag the mouse to move the sample into position. 3. Scroll to focus. 4. Select the test method and .The size of the sample can also affect results, . According to ASTM A370, [12] the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55 mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, .

The hardness is read within one second (or as specified by the customer) of firm contact with the specimen. Specimen size: The test specimens are generally 6.4mm (¼ in) thick. It is possible to pile several specimens to achieve the 6.4mm thickness, but one specimen is preferred. Data: The hardness numbers are derived from a scale.Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes 8.8 - 12.9. In the event of arbitration, the Vickers hardness test shall be used as reference.

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. . or where the sample size or sample shape prohibits its use. The Rockwell method measures the permanent depth of .Enhance your products’ material durability and compliance with Micom’s ASTM D2240 shore hardness testing services for plastics, polymers and rubber. Learn more. . Number of samples or products: 1 sample, 5 measurements; Sample size: 2″ X 2″ or larger with a minimum thickness of 0.64 mm (0.025 in.) Conditioning and testing temperature .Uncured materials will show low hardness. Size of the material – Testing the hardness of thin materials can be difficult. Hence it is important to check the size specifications of the material. What are the test methods to measure Shore D Hardness? The test methods used to measure Shore D Hardness are: ASTM D2240 and ; ISO 868

Hardness mapping refers to the creation of a comprehensive hardness curve for a specimen or a specific area. The hardness curve can be determined through the equal distribution of test points across the entire specimen. The result – the hardness map – can either be shown as a 2D colour image or a 3D diagram.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Download scientific diagram | Standard Specimen Size for Micro Hardness Testing (L= 30mm, W= T= 6mm) from publication: Influence of Current on Microstructure and Hardness of Butt Welding Aluminium .Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled .

During specimen testing or coupon block verification, the spacing between indents, as well as from the material edge, must be properly maintained to prevent any adjacent indents or worked edge from influencing the next test. . the hardness of the material; the size and shape of the indentation; and the diameter of the test piece. If testing .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell . The Knoop and Vickers techniques are referred to as microindentation-testing methods on the basis of indenter size. Both are well suited for measuring the hardness of small, selected specimen regions .

This means that the size of indentation left by the indenter is measured to determine the hardness value of a test specimen. Indenter shape and material: The indenter is an equilateral pyramid (with a square base) made of diamond with a plane angle of 136°.Rockwell Hardness Testing Machine HR-530 Series Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of plastics (A & B) and Light Force Brinell hardness testing. HR-530 (810-233-23A) Maximum specimen size: Height 250 mm, Depth 150 mm HR-530L (810-333-23A) Maximum .This means that the size of indentation left by the indenter is measured to determine the hardness value of a test specimen. Indenter shape and material: The indenter is a tungsten carbide metal ball, with a diameter of 1, 2.5, 5 or 10 mm, .

The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. . Specimen size: A standard specimen of 6.4mm (0.25 in) thickness is either molded or cut from a sheet.Steps for taking permeability test. Step 1: Green sand is rammed under the sand rammer to prepare the sand specimens. A 5cm x 5cm standard specimen of sand is used. Step 2: The sand specimen is held by a tube called "sand specimen tube." This standard specimen has Height =H in cm and Area = A in cm².IV. Test Specimen. Any standard does not specify the test sample’s size or form. The test piece shouldn’t have any bulges or marks on the side or opposite of the indentation that would indicate the impact of the indenter’s force. At least ten times the size of the depression should be the thickness of the test sample. The hardness of the specimen is quickly read within one second of establishing firm contact. ASTM D2240 Test Specimens. Specimen Detail: The specimens tested by ASTM D2240 are made of rubber, plastic or other soft materials. Specimen Size: The test specimens typically have a thickness of 6.4 mm (¼ inch).

Rubber Flex Cracking Tester service

standard hardness testing methods

Rubber compression stress relaxation Tester service

how to measure hardness

WEBMaria Filo has 5 Verified Coupon Codes. Top Coupon Including Sign Up Now And Get 15% Off & 60% Off On All Sale Accessories. Exclusive Offer, Make your purchase $150or plus and get free shipping on all orders. Order over $150 and get 10% off on your purchase. If you are not happy against your order you can return it within 30 days.

hardness test specimen size|how to measure hardness